Textile Industry Solutions

As a designer of automation solutions for textile equipment companies, Qanbay offers customized sensors and system solutions for all types of textile companies to solve the problems encountered by textile companies during production operations. The problems that we can solve for you are: reducing labor costs; improving production efficiency and production quality; reducing energy consumption, achieving green production; efficient command and intelligent control. We have been providing products to customers in textile industry for 20 years, and excellent quality has been accepted and recognized in this industry. Our product quality, staff service and professional are all Qanbay brand guarantees, providing customers with professional solutions.

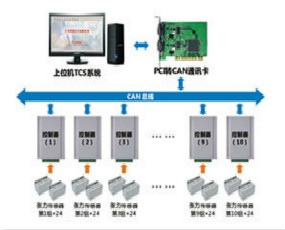

Tension monitoring system

The online tension monitoring system consists of wire detector, tension sensor component and data processing host, etc. The main function is to provide a reliable and intuitive tension indication for production, timely identify the problematic spindle pos

Tension sensor

Qanbay tension sensors are widely used in textile and chemical fiber industries to detect yarn tension during use. The Qanbay tension sensor converts the tension acting on the yarn into a weak voltage signal.

Read more

After passing through filter circuit, amplification circuit, linear compensation circuit, starting point adjustment circuit, the weak signal is amplified, compensated and sent to the final amplifier circuit to amplify the output and form a voltage signal which is linear with tension. Qanbay tension sensor is made of metal, easy to install and durable. The elastic strain gauge is made of ceramic material, which has long service life and high reliability. In order to meet different customer needs, Qanbay tension sensor has various ranges and multi-size specifications, and products can also be customized to meet different customer needs.